De technische realisatie van StoryBOX is in handen van Bas Withagen, die op de website van Fablab Amsterdam het volgende noteerde over de totstandkoming van het tweede werkende prototype in november 2010:

For building the boxes that contain the individual sounds for StoryBOX, I needed to tackle some specific design challenges.

The boxes needed to:

- have a transparent part for the infra-red communication

- be charged in some way

- hold the necessary electronics

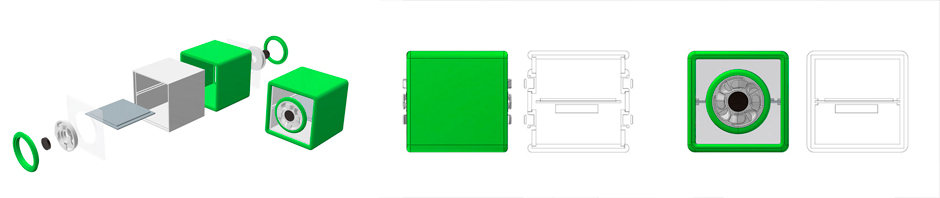

- be small/big enough to handleThe first item was tackled by finding a supplier who could supply an ir-transparent acrylic. I made circular holes in the acrylic for this plastic so the orientation of the block in relation to the other blocks would not matter optically. The ir-transparant circles were made slightly bigger than the holes to compensate for the material removed by the laser (13.0 mm and 12.8 mm respectively).

To be able to mount the ir-transceiver in the right position and to prevent ir-light leaking Ii needed to make a spacer. This spacer was made from normal 3-mm acrylic. The inside diameter fits snugly around the ir-transceiver and the outside diameter is slightly bigger than the hole in the box. This way I was also able to secure the ir-transparent piece to the box. The boxes themselves (56 mm x 56 mm) are done on one single line with no extra room between the sides. This would limit the material waste but would also mean that the boxes would not be press-fit.